Fenner Precision Polymers

Fenner Precision Polymers, a Michelin Group Company, based in the heart of Lincoln, UK, develop and manufacture elastomeric materials for a range of industrial applications.

Download Exemplar Study

Collaborative use of Tribometry to Enhance Elastomeric Product Performance

Fenner Precision Polymers, a Michelin Group Company, based in the heart of Lincoln, UK, develop and manufacture elastomeric materials for a range of industrial applications. Fenner Precision Polymers’ products are required to withstand a wide range of demanding operating conditions and improving product lifetime is a key customer demand.

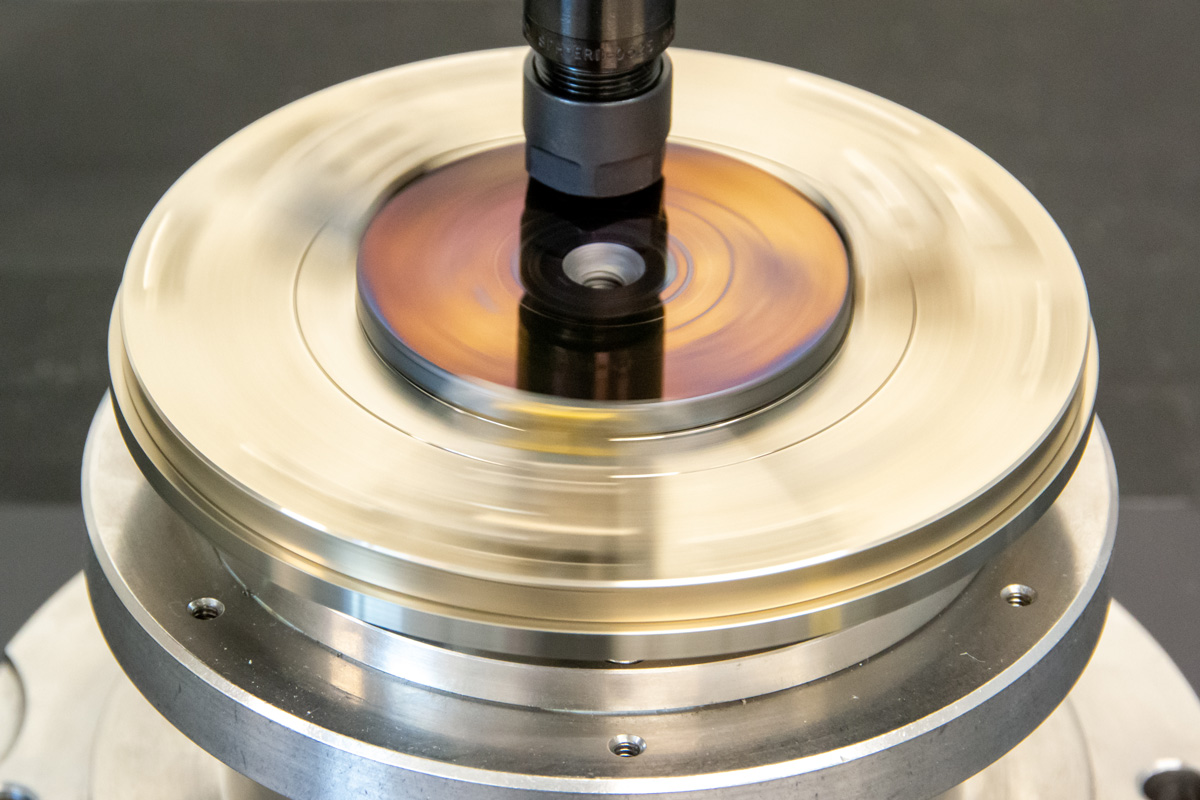

Tribometry is the study of wear using techniques such as the “pin on disc” method to apply known forces between two materials of interest. As such, the Rtec MFT 2000 Tribometer, located in the Bridge, was the ideal tool to help Fenner Precision Polymers understand and benchmark the wear properties of a current conveyor belt product and allow comparison with re-formulated product designs.

The MFT 2000 instrument can be configured in a number of different ways to allow different testing regimes to be applied to materials of interest such as rotating and reciprocating contact regimes and measurements at high (up to 500oC) temperature. The instrument provides a range of outputs to characterise wear properties including the co-efficient of friction, material hardness and depth of wear.

Application of tribometry to Fenner Precision Polymers industry challenge allowed them to characterise the wear behaviour of their elastomer materials in use without the need to scale up to production trials which are costly and take up manufacturing time. Ultimately, by improving the wear resistance of the material, it was envisaged that Fenner Precision Polymers would be able to increase their product offering and strengthen customer relations.